Product 4: TreasurePrint! Solve 3D Riddles, Win Prizes

I love scavenger hunts. I love 3D printing. I love prizes.

I've also had a great year in my business, Prototyping Tech, and want to give back this holiday season with an opportunity for anyone to join me for a few of my favorite things in this free, fun offering: TreasurePrint!

All the models are still live, so feel free to play. However, please know that all of the prizes have been awarded as of January 1st, 2025.

Here's how it works: For three weeks I'll release a new CAD model designed for FDM Printing without any support structures. Each CAD model contains the answer to a riddle.

Everyone who submits the correct answer to the riddle by the deadline will be entered to win that week's prize.* The first person to solve and submit any correct answer will be rewarded with 3 extra submissions of their name into that week's raffle!**

These should be solvable by printing the models or viewing in a CAD program like OnShape, or even slicing software like Bambu Studio. Each design will also help you learn some basic principles of 3D printing (even if you don't have a printer).

The Final Clue

A link to the third CAD Model is downloadable here. You can also view it online here with Autodesk Viewer. Since my last clues have gotten "too easy" feedback, you may answer any or all of the 4 questions listed below about this Clue. For every correct answer, you will get another submission into the raffle for the Bambu Lab Printer!

Submit your answers here :)

Questions (each correct answer will give you another submission for the grand prize!):

- How many separate parts compose Clue 3?

*Note: they can all be printed in place without support* - What is the type of object that needs to be embedded in two of the Clues for the system to function properly?

- Which of the two Clues require this type of embedded item?

- Generally, how do you actuate Clue 3?

Last Clue: First Hint

The "embedded item" referred to in questions 2 and 3 is not printed, and I was able to buy a pack of 100 for under $10.

Last Clue: Second Hint

The names I have used for the Clues in my own notes are:

Clue 1 is the KEY

Clue 2 is the GLOBE/ENCLOSURE

Clue 3 is the LOCK.

Last Clue: Last Hint

The embedded objects aren't the Strongest, but if they get to close and Square Up for a fight, they can be tough to pull apart.

The Clues Assemble together to make an ornament, and have a spot to hide and secure notes to rediscover next year :) If you print in a translucent material an electric tea candle can give it a nice glow.

Week 3 Learning: Embedding objects and printing mechanisms

I'll add more here soon regarding some of what I needed to learn in order to effectively design Clue 3.

Main learnings include design principles for

-press fit embedded objects

-multi-element mechanism to self retain each of it's pieces with space to print in place without fusing together.

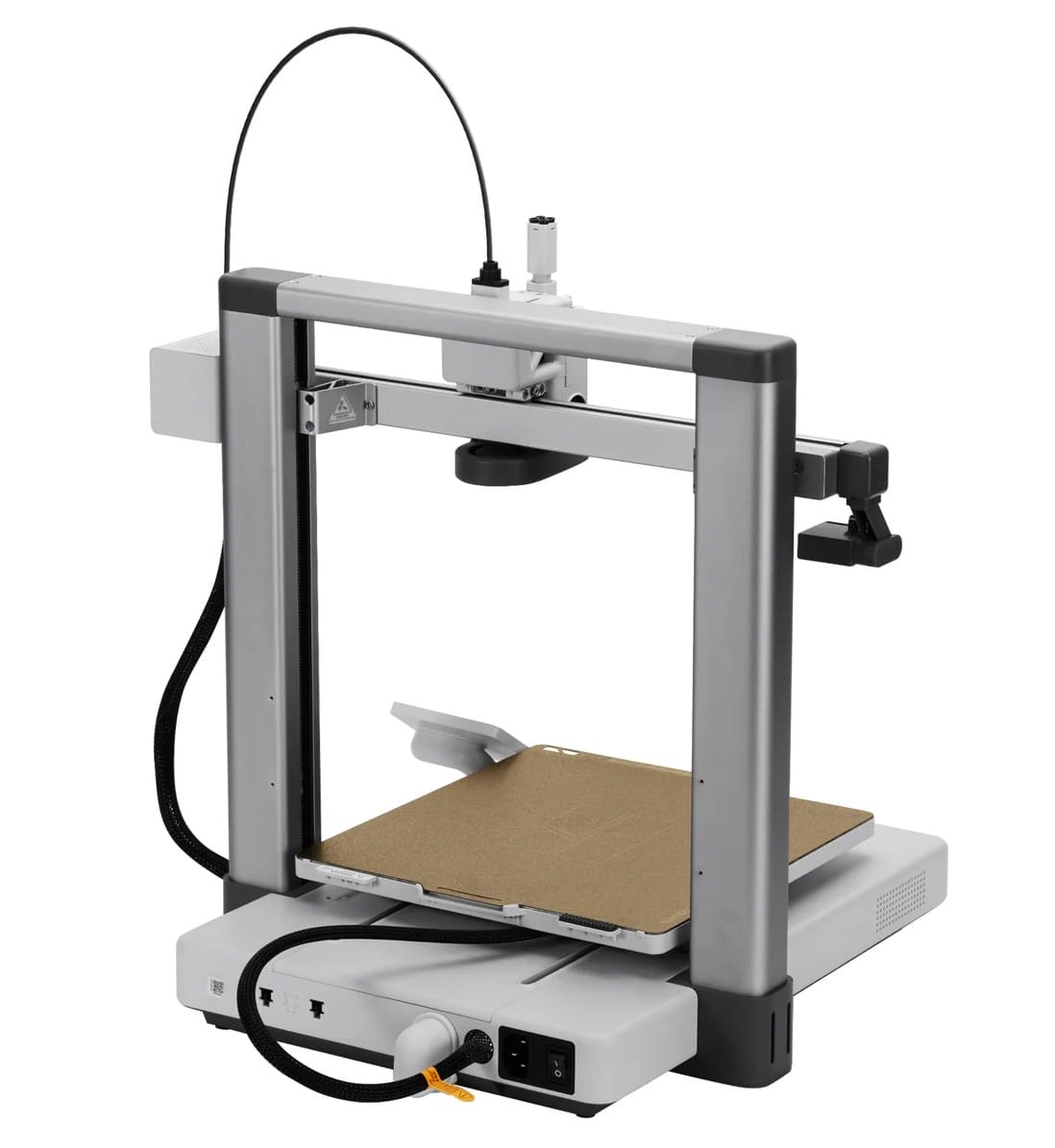

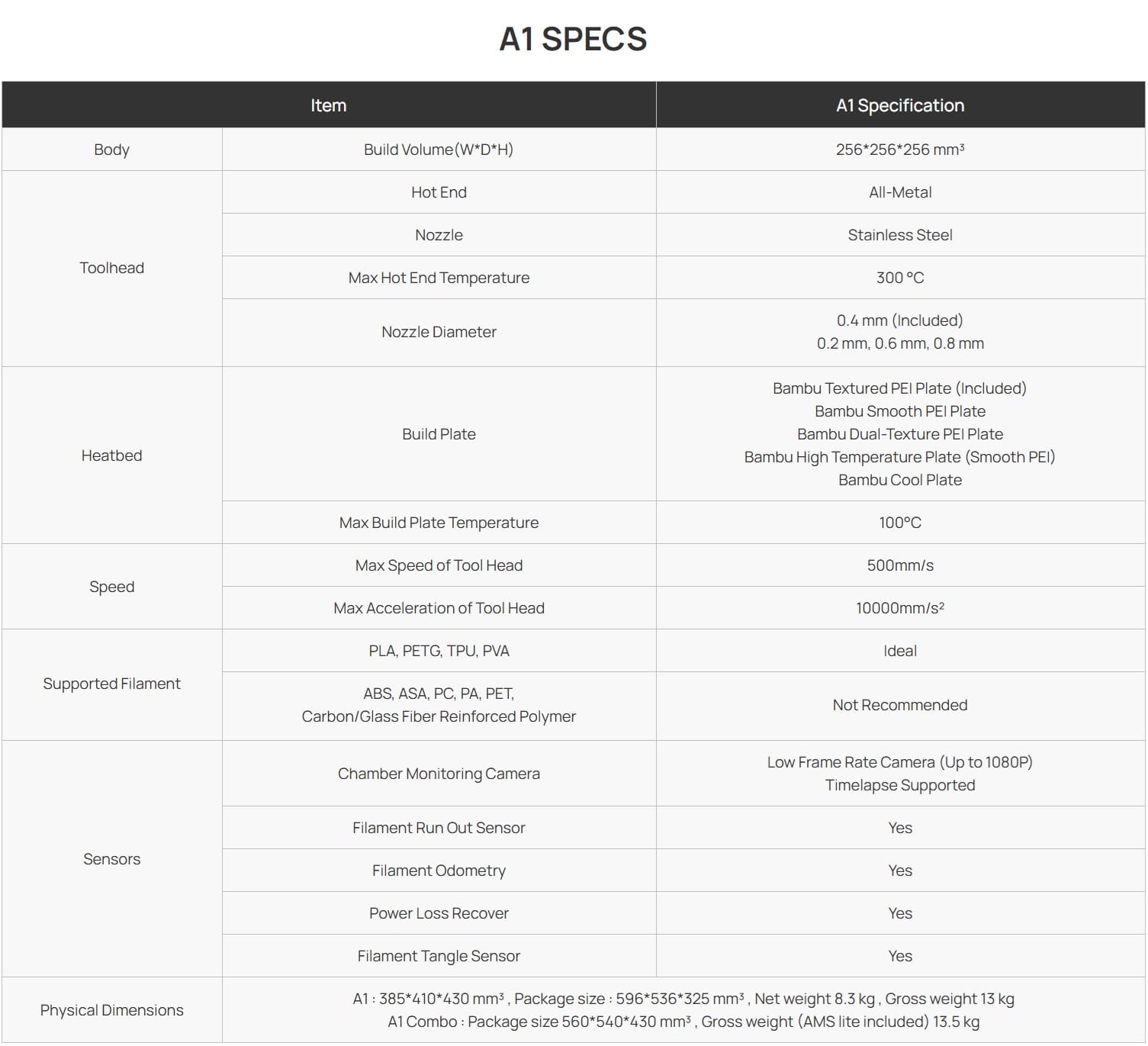

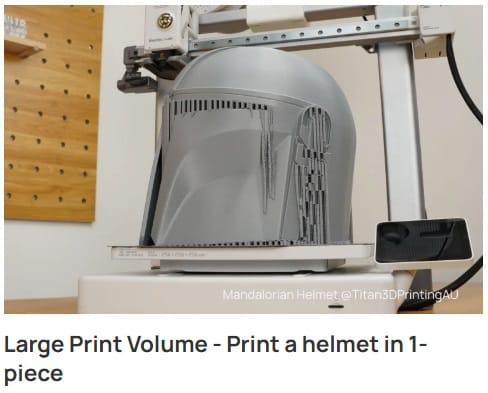

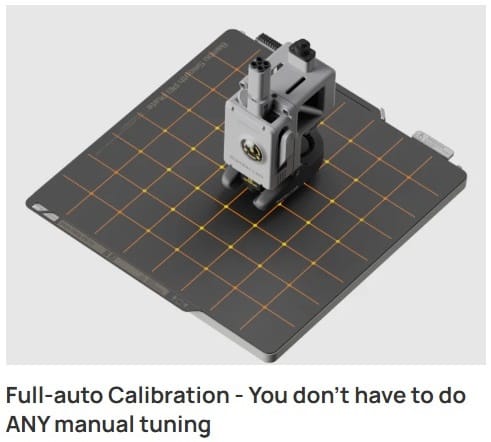

The Week 3 Riddle winner gets the Grand Prize: This Bambu Lab A1 3D Printer!!

Product Page: https://us.store.bambulab.com/products/a1?variant=41583355199624

Grand Prize Winner: Scottie from WA!

Week 2 Clue

A link to the second CAD Model is downloadable here. You can also view it online here with Autodesk ViewerThe model is showing a special relationship, based on feedback from the first riddle, I made this clue harder. Please submit the name of the relationship that this CAD model is trying to communicate 😄

Submit your answer here!

Week 2: First Hint

The answer to this clue is irrational.

Week 2: Second Hint

Even though it seems like it can go on forever, you can submit an answer that is just 1 or 2 characters...depending on the alphabet.

Week 2: Last Hint

There's some circular logic to this answer 😏

As a side bonus: Clue 1 + 2 can be assembled into a holiday ornament :)

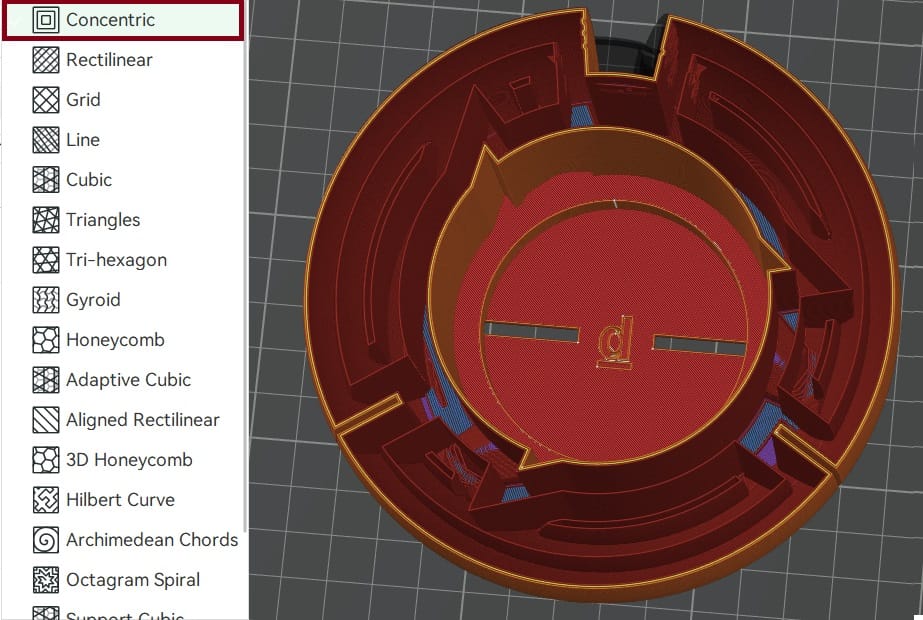

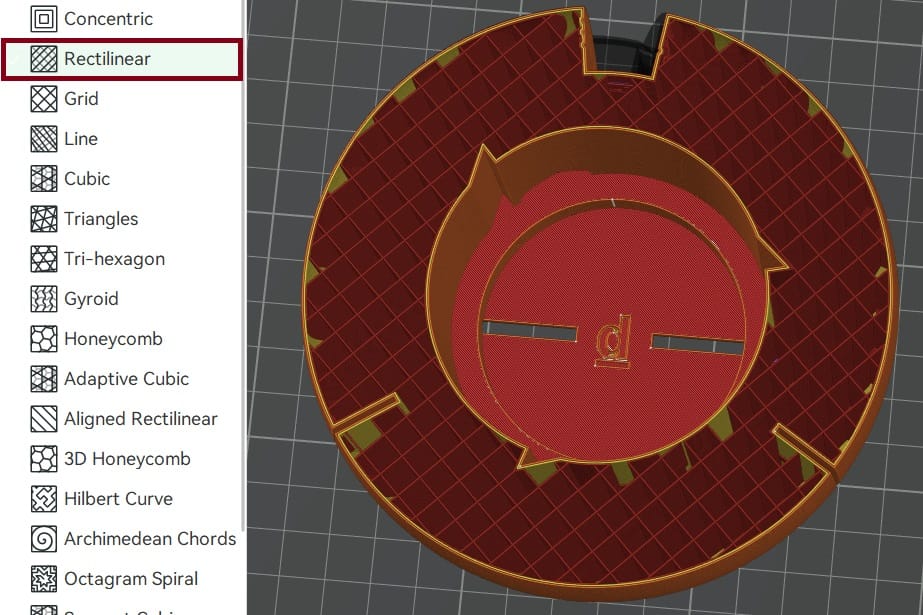

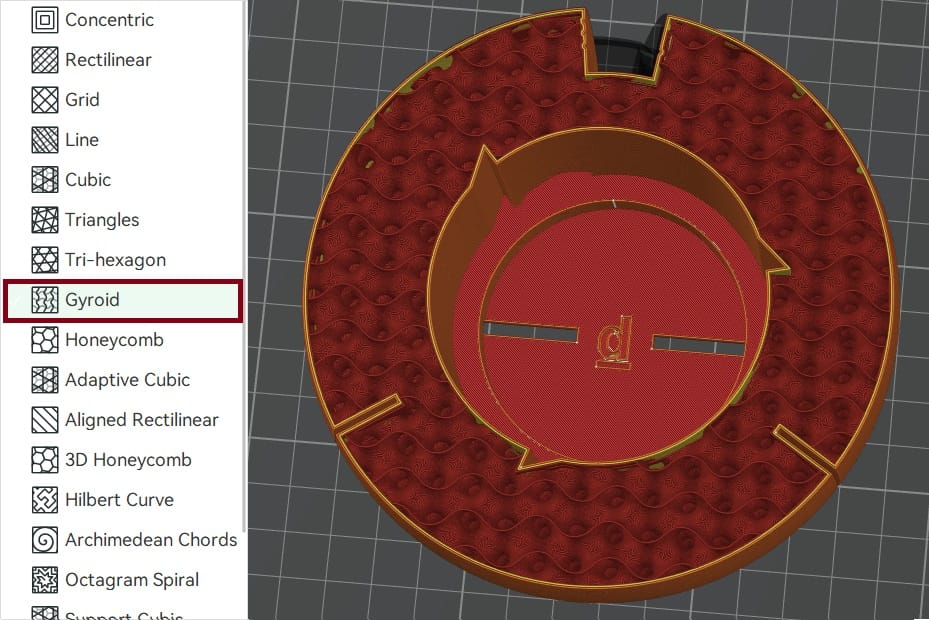

Week 2 Learning: Infill & External Layers/Loops

Infill: When 3D printing a part, you have options regarding how the internal volume of the part will be filled. This is something you get to specify in your slicing software.

The two main considerations are:

1) What Density of fill would you like, expressed as a percentage?

-Primary impacts of density include total material use, time to print, strength and weight.

2) What type of pattern would you like this infill to follow?

-Primary impacts include strength and printability. (In this case, when using translucent material there is also an aesthetic impact).

External Layers and Loops: You can specify the number of layers on the bottom and top of your part, before the lower density infill takes effect, as well as the number of beads of plastic form the walls of the part.

Similar tradeoff's between strength, weight, material use, and time to print are factors here. I will say that I tend not to go below 2 layers on the bottom/top/walls for strength and aesthetic reasons.

When printed in a translucent material and lit from the inside, I think it looks nicer with the concentric infill pattern vs gyroid infill or the rectilinear.

Week 2 Winner: John P from St. Louis!

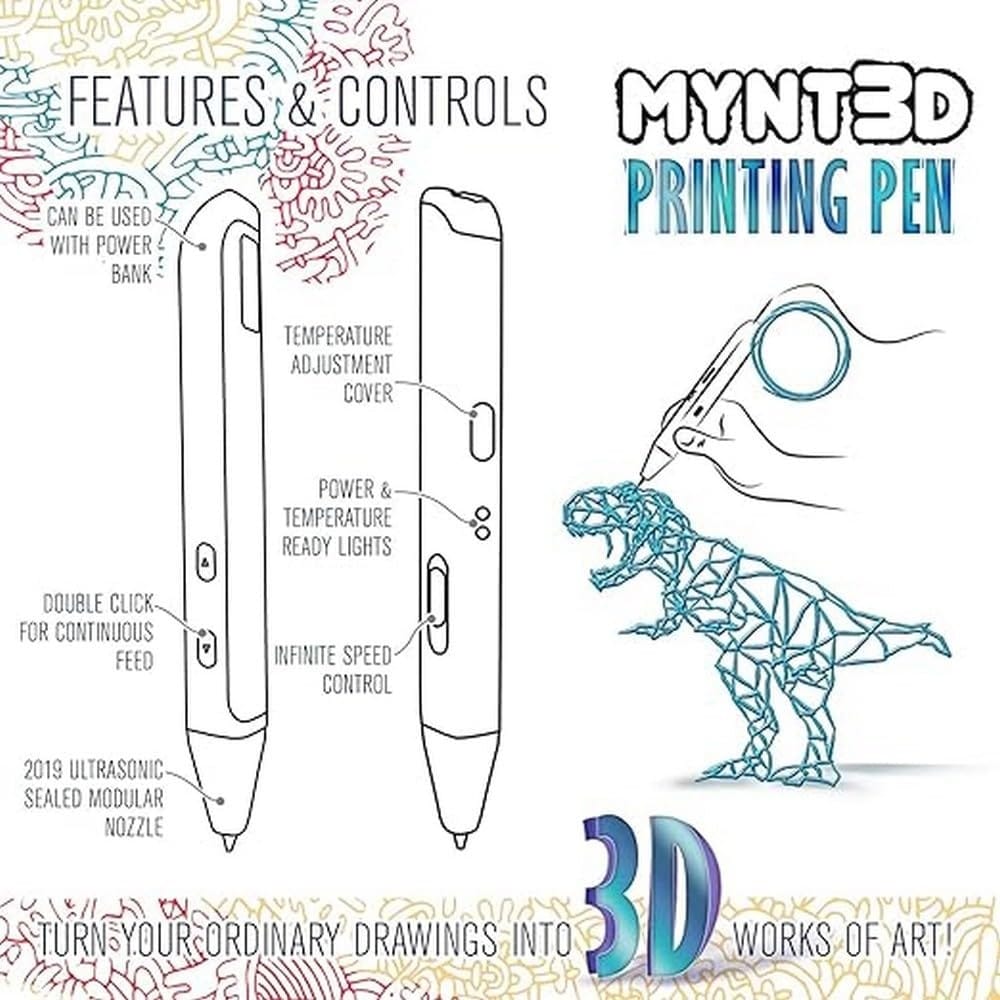

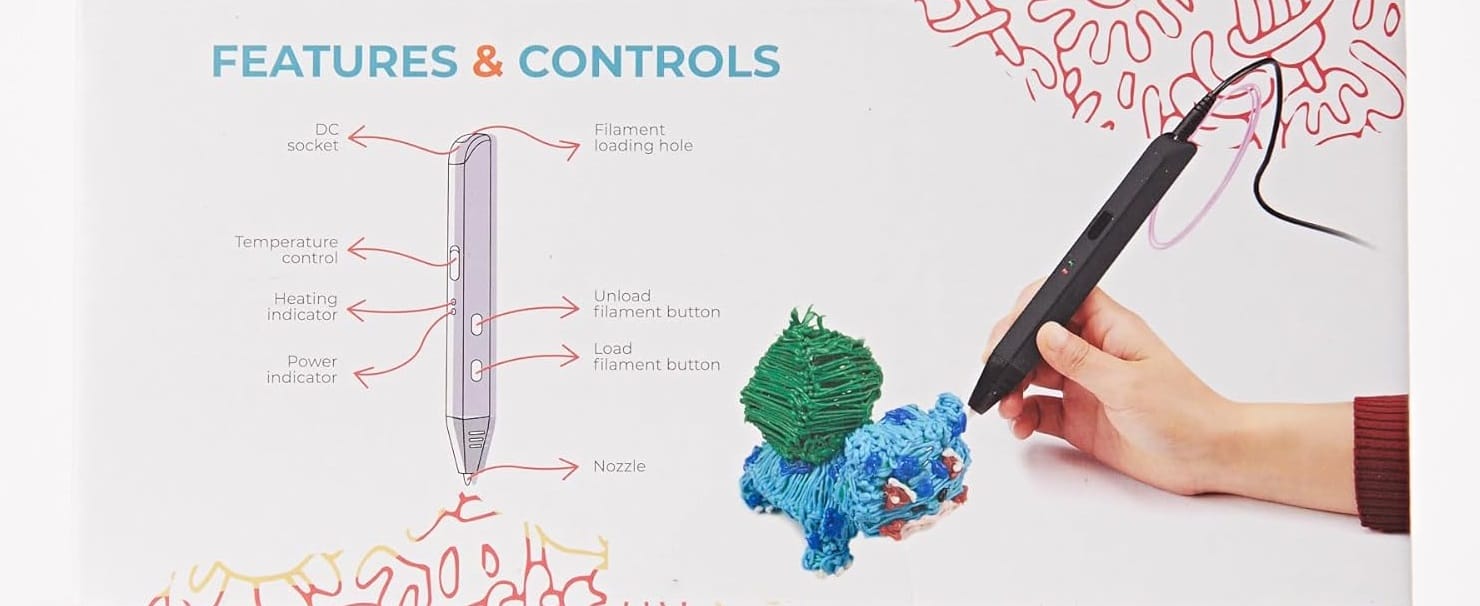

Product Page: https://www.amazon.com/dp/B081C946ZJ?ref=ppx_yo2ov_dt_b_fed_asin_title

Week 1 Clue

Link to Drive Folder with STL FileShort Video of the Clue 1 CAD Model

Week 1: First Hint

A feature of this part points to an address.

Week 1: Second Hint

If your phone asks this part where to go, you'll get a Quick Response.

Week 1: Last Hint

Take a look at the base of the part...does the pattern take you somewhere? 😉

Week 1 Learning: Types of 3D Printing, Overhangs & Orientation

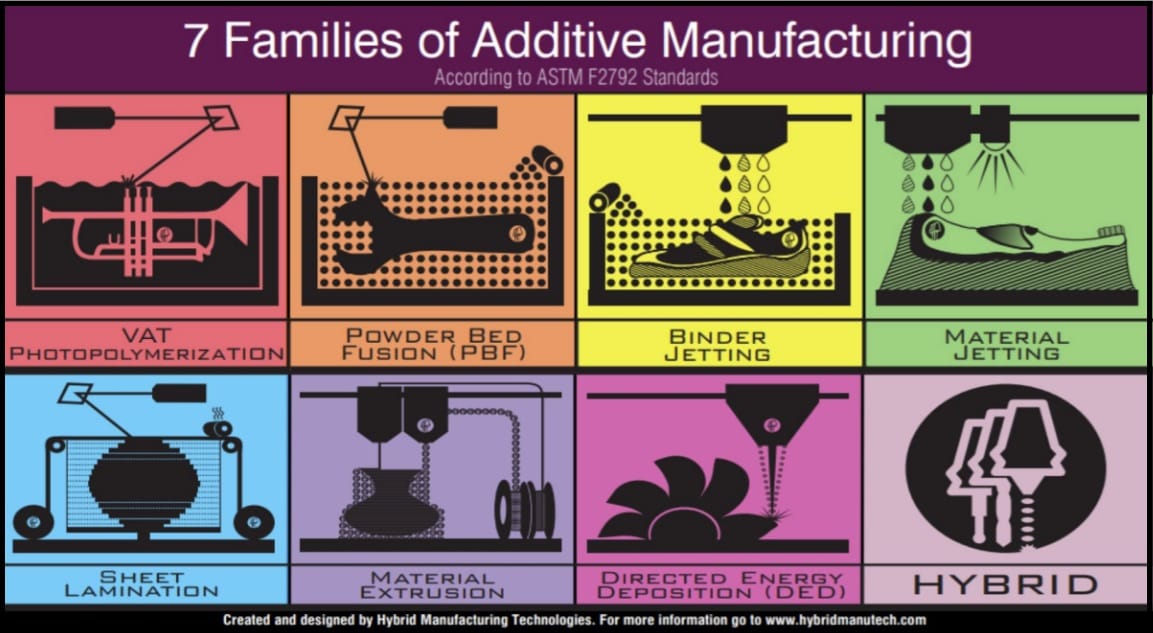

3D Printing AKA Additive Manufacturing (AM) is a broad category of manufacturing where material is added to a workpiece based on a 3D model. Polymers are the cheapest and easiest to work with, however, metal, ceramic and hybrid materials are also possible to fabricate in this way.

The prizes of TreasurePrint are focused on the most common type of consumer printers that melt and extrude plastic filament, a process call Fused Deposition Modeling (FDM). In keeping with that theme, all of the CAD models this month have been designed and optimized for printing with that method. A few items to note about this first model:

1. There is a larger flat surface that is meant to be the base layer of the print and lay directly onto the build platform.

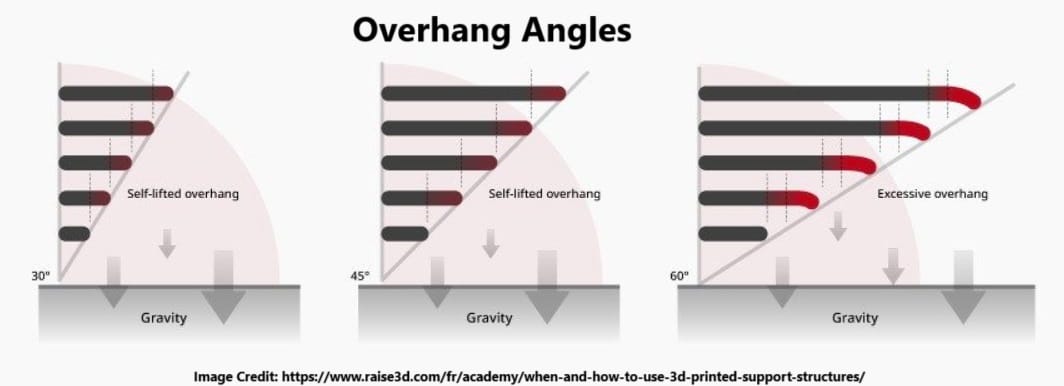

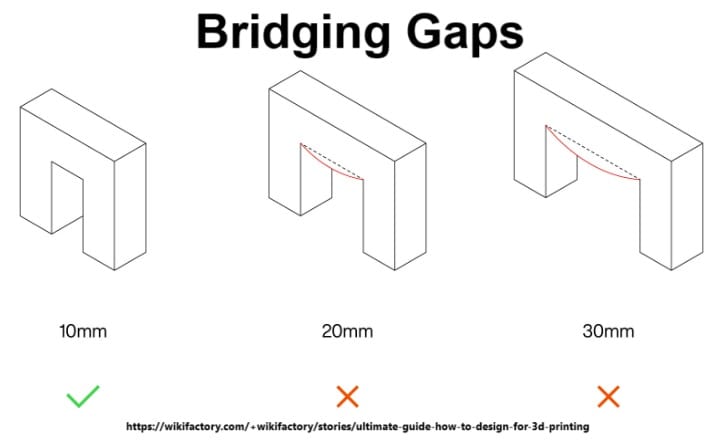

2. Even though there are overhangs (like the arched handle on top), most surfaces in the model extend at an overhang angle less than 45°. This angle is a good rule of thumb for most FDM printers to avoid the need for support structures. That said, there are a few very small features that break the 45° rule and are able to bridge a small gap without any support.

WikiFactory has a good design guide when you're getting started and want a rundown of the basics.

Supplemental images for week 1 learning

Week 1 Winner: Joe C from MO!

Product Page: https://www.amazon.com/dp/B08LMVQWYF?ref=ppx_yo2ov_dt_b_fed_asin_title

Good Luck Everyone and Hope You Have Fun!!

*Prizes will be shipped to the winners anywhere in the contiguous USA for free. If the winner's shipping address is outside of the contiguous USA I may ask for the winner to pay shipping costs.

**JoshAdams.io reserves the right to make adjustments to this Riddle-Raffle-Offer at any time for any reason.